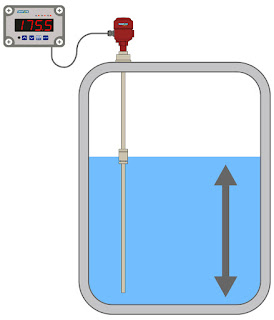

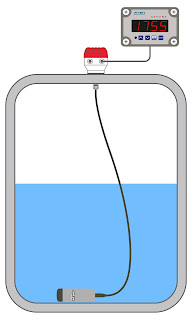

To run the industrial process successfully we use lots of instruments in industries. The level sensor is one of the most important devices that we use in industries but only a few people have the proper idea of how a level sensor actually works and the reason is, that the level sensor available in today’s market is too hard to work with. Most of them are just a giant box of complexity. But levelpro tank level sensor is an exception. This is a masterpiece creation of modern science and you can be sure that this device will work surprisingly well.

|

| Tank Level Sensor |

A Levelpro tank level sensor has a 4-segment display. Most importantly, the sizes of the characters are absolutely standard. The upper line characters are 12 mm and the lower line characters are 6 mm in dimension. So, you can easily understand how user-friendly the monitoring system of a Levelpro tank level sensor is. The accuracy rate of a Levelpro level sensor is simply mind-blowing. The terminal point accuracy of this device is 0.5% and the optional accuracy is 0.25%. So, undoubtedly the accuracy of this device is really a matter of wonder to the industrial experts. Your decision to choose this device will surely be a great investment for your industry and you have lots of good reasons to choose it.